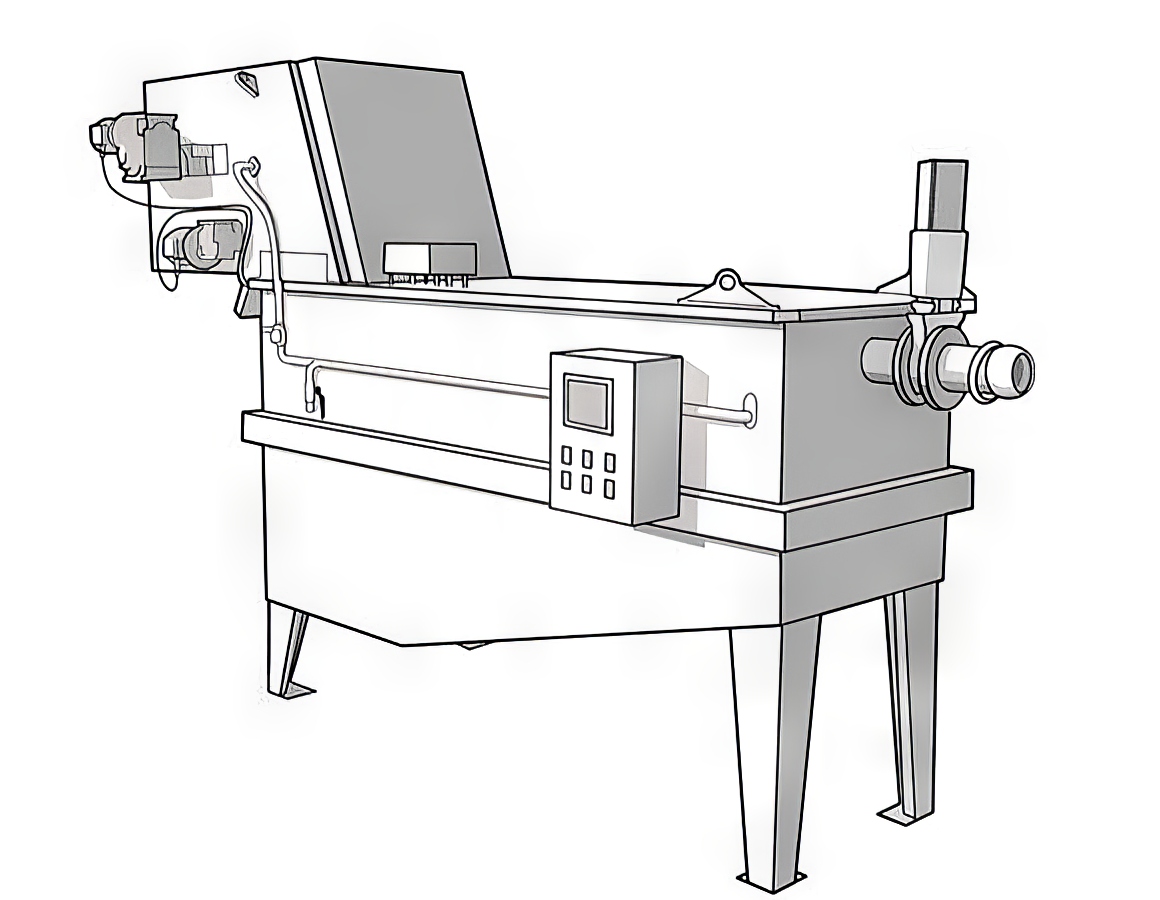

TANKER RECEPTION SYSTEM

Special machine designed for the pre-treatment of sewage from cesspools.

Alternatively, it can be used in the zootechnical and agronomic fields (instead of the rotary screen) to separate the liquid part, to be used for fertirrigation, and the solid part, to be used for composting.

The spoil pre-treatment plant consists of three machines:

Filtrostar automatic separator;

Containment tank;

Automatic regulation and control systems.

FILTROSTAR Standard Grid: The containment tank, made entirely of AISI 304 stainless steel, completely encloses the grid and control systems, eliminating any problems due to splashes, bad odours, spillage, etc. It guarantees a working environment in line with any hygienic requirements.

The tank comes complete with a ø 100 mm spherical quick coupling, allowing the operator to empty the tank truck by gravity or by pumping easily, quickly and safely.

The grid is automatically activated when the slurry enters; if the level inside the tank reaches the preset maximum limit, a pneumatic valve closes the tank inlet. As soon as normal level conditions are restored, the valve reopens and the disposal cycle begins again.

During the processing cycle, a washing ramp with a solenoid valve sprays water onto the filter belt, keeping it constantly clean.

When the slurry inside the tank reaches the minimum level, the self-washing device (both tank and screen) comes into operation.

The spoil treatment plant can be completed with the combination of a compactor and an auger or static desander.

The former, mounted below the discharge point, allows the dewatering of the extracted solids, reducing their weight and volume; the latter, positioned to the side, is able to separate even the smallest suspended particles in the screened slurry. This completes the treatment, obtaining a desanded liquid part free of any solid waste, and a dewatered solid part, compact and eventually bagged.