Dehydrates, compacts, conveys solid residues from filtration or screening of civil and industrial wastewater.

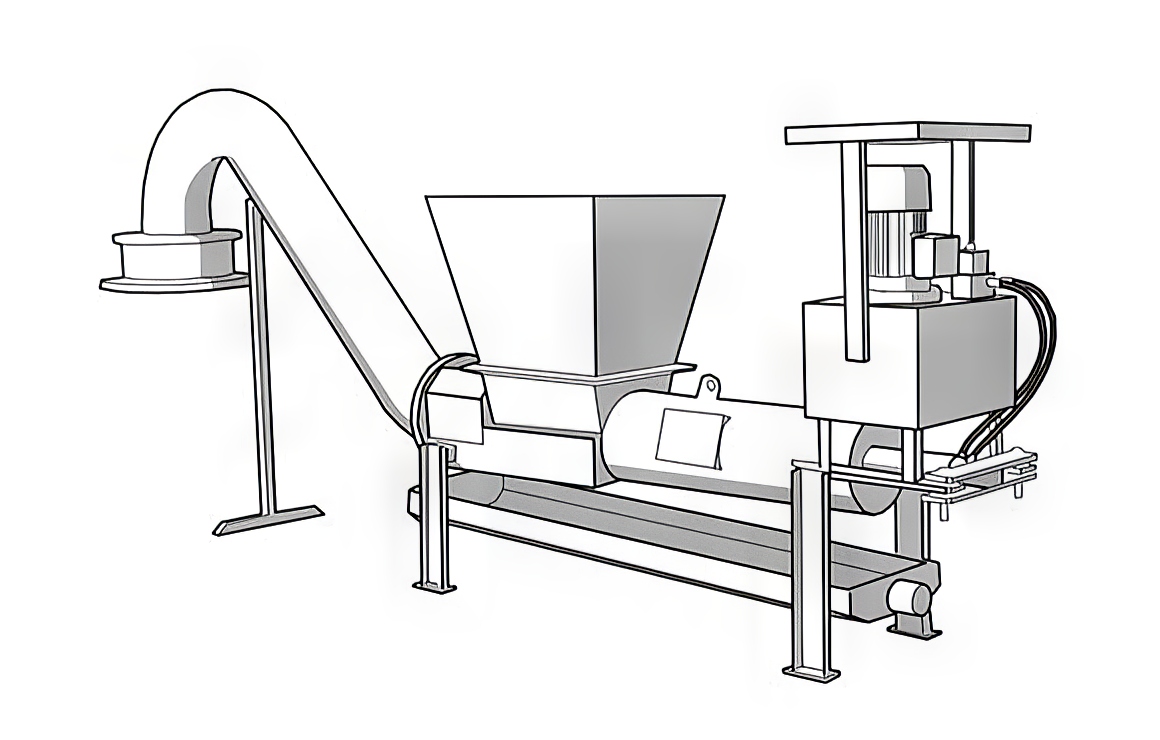

A hopper receives the filtered material; a hydraulic piston operated by a hydraulic control unit compresses and dehydrates the solids inside the cylinder, which is perforated and allows the drippings to escape, collected in a special tray.

Depending on the needs of the installation site, the dimensions of the hopper, the length and the inclination of the tube are adapted. All components are oversized to ensure robustness and durability.

The hydraulic compactor is built in AISI 304 stainless steel, including the hopper, the control unit and the drip tray.

At the end of the tube, a semi-automatic system can be applied for bagging the compacted solids into a continuous LONGOPAC bag, which allows transport to the storage site with maximum hygiene.

DEHYDRATION: The screened material is dehydrated, the drippings come out of the special holes made on the compression chamber and collected in a special tray.

COMPRESSION: The volume of the solids is drastically reduced up to 25% of the original volume, reducing transport and disposal costs.

TRANSPORT: The compactor conveys the pressed material to the collection container via a closed tube, which guarantees maximum hygiene. The tube can be applied at all inclinations. This transport and lifting function allows you to avoid the purchase of additional machinery such as a conveyor belt or a screw feeder.